Nitroglycerin isn’t something you find on a pharmacy shelf, but it’s a compound that saves lives every day. While it’s best known as the key ingredient in dynamite, its medical use in treating angina and heart attacks goes back over 140 years. The process to make it isn’t simple, and it’s not something done in a garage. It’s a tightly controlled, highly dangerous chemical reaction that requires precision, specialized equipment, and strict safety protocols. If you’ve ever wondered how a substance that can blow up a building also helps someone breathe easier after a heart attack, here’s how it’s made - from raw materials to the final product.

Raw Materials: Glycerol and Mixed Acids

The entire process starts with two basic ingredients: glycerol and a mixture of concentrated nitric and sulfuric acids. Glycerol, also called glycerin, is a colorless, odorless, sweet-tasting liquid. It’s commonly found in soaps, cosmetics, and food products. But for nitroglycerin production, it’s not the food-grade kind. Industrial-grade glycerol with at least 99% purity is used because impurities can cause unstable reactions.

The acid mixture is the real danger zone. It’s typically 60% nitric acid and 40% sulfuric acid by weight. The sulfuric acid doesn’t react directly - it acts as a dehydrating agent, pulling water away from the reaction to push it toward completion. This mix is called mixed acid, and it’s stored in corrosion-resistant tanks made of lead-lined steel or specialized plastics like HDPE. Even a small spill can eat through metal or cause severe burns.

The Nitration Reaction: Controlled Chaos

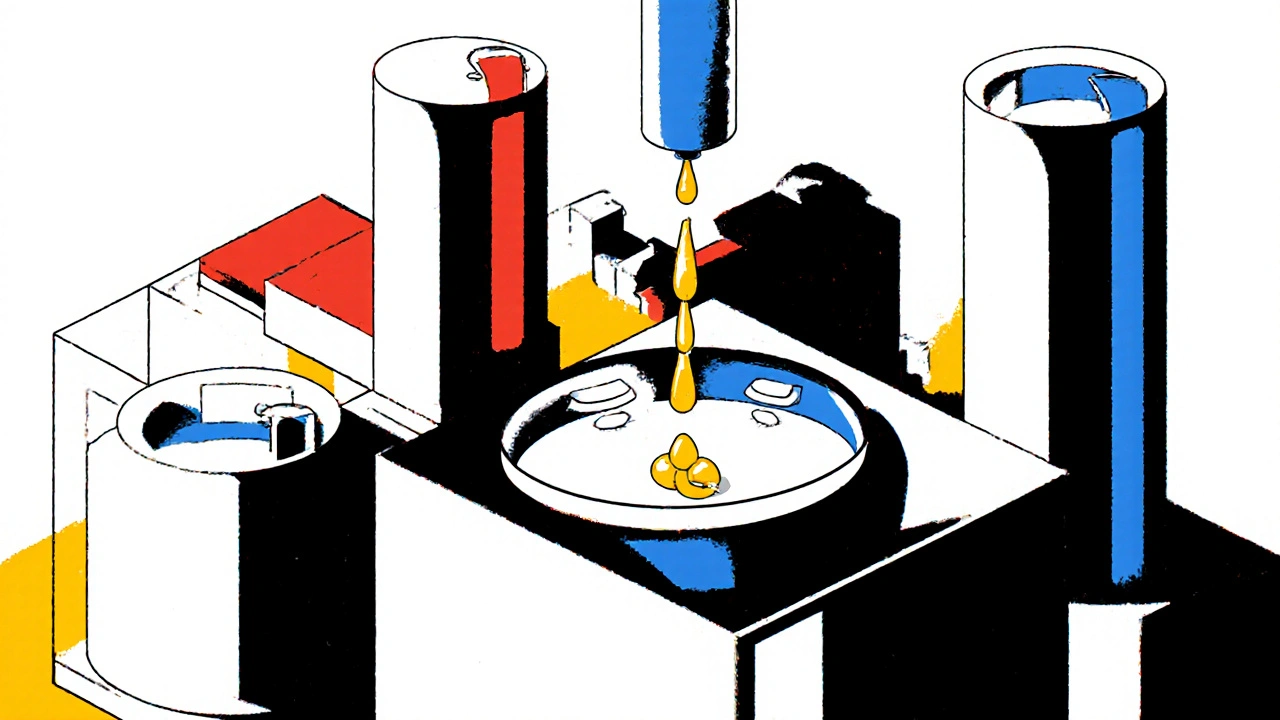

The actual reaction happens in a reactor designed to handle extreme heat and pressure. Glycerol is slowly dripped into the cold mixed acid - usually kept between 10°C and 15°C. The temperature control is critical. If it rises above 20°C, the reaction becomes uncontrollable. Nitroglycerin starts decomposing around 50°C, and at 120°C, it explodes spontaneously.

As the glycerol enters the acid, it undergoes esterification. Each of glycerol’s three hydroxyl groups (-OH) loses a hydrogen atom and bonds with a nitro group (-NO₂) from the nitric acid. The chemical formula changes from C₃H₈O₃ to C₃H₅N₃O₉. This reaction is exothermic - it releases heat. That’s why the reactor is surrounded by a cooling jacket filled with chilled brine or glycol. Temperature sensors feed data to automated controls that adjust the drip rate in real time.

This step takes about 30 to 45 minutes per batch. A typical industrial reactor holds 500 to 2,000 liters. One batch produces roughly 400 to 1,600 kilograms of crude nitroglycerin. But it’s not pure yet. It’s a thick, oily liquid mixed with leftover acid and water. And it’s extremely sensitive.

Separation and Washing: The Most Dangerous Step

After the reaction completes, the mixture is transferred to a separator. Because nitroglycerin is denser than water and doesn’t mix with it, it sinks to the bottom. The upper layer - mostly spent acid - is drained off and recycled. What’s left is crude nitroglycerin contaminated with traces of acid.

This is where most accidents happen. Even a tiny amount of acid left in the nitroglycerin can cause it to decompose over time. So the washing process is meticulous. The crude product is washed in cold water, then in a sodium bicarbonate solution to neutralize any remaining acid. Each wash cycle is followed by settling and draining. This happens in a series of 3 to 5 wash tanks, each separated by blast walls.

Workers don’t handle the material directly. All transfers are done remotely using pneumatic pumps and closed-loop systems. Cameras monitor every step. The entire washing area is kept under negative air pressure to contain any vapors. And no metal tools are allowed near the nitroglycerin - even a spark from a wrench can set it off.

Stabilization: Making It Safe to Store

Even after washing, nitroglycerin is still unstable. It naturally breaks down into nitrogen oxides and glycerol dinitrates, which are even more sensitive. To prevent this, stabilizers are added. The most common is 0.5% to 1% of dibutyl phthalate or urea nitrate. These chemicals slow decomposition and absorb any free acids that might form.

The stabilized nitroglycerin is then filtered through fine paper or ceramic filters to remove any solid particles. These particles can act as ignition points. After filtering, the liquid is tested for acidity using titration. If the pH is above 7, it’s considered safe for storage. If not, it goes back for another wash.

Final Product: Liquid vs. Incorporated Form

There are two main forms of finished nitroglycerin: pure liquid and incorporated into a solid matrix.

Medical-grade nitroglycerin is always the pure liquid form. It’s diluted with ethanol and stored in small, amber glass bottles under refrigeration. Each bottle contains about 0.5 milliliters - enough for dozens of sublingual doses. The concentration is typically 2% to 4% nitroglycerin. This version is used in heart medications like nitroglycerin tablets and sprays.

Industrial-grade nitroglycerin is mixed with absorbent materials like kieselguhr (diatomaceous earth) or cellulose to create a paste. This is what Alfred Nobel used in 1867 to invent dynamite. The paste is safer to handle because the absorbent material reduces sensitivity to shock. This form is used in blasting caps, demolition charges, and some mining explosives.

Safety and Regulation: Why It’s Not Made in Backyards

Nitroglycerin is classified as a Category 1 explosive under UN regulations. In the UK, its manufacture is regulated by the Health and Safety Executive (HSE) under the Explosives Regulations 2014. Only licensed facilities with blast-resistant buildings, remote operation systems, and emergency shutdown protocols are allowed to produce it.

Every batch is tracked with a unique serial number. Production logs include temperature, acid ratios, wash cycles, stabilizer amounts, and final purity tests. Inspectors show up unannounced. If a facility fails three inspections in a year, its license is revoked.

There’s a reason no one makes nitroglycerin at home. The margin for error is razor-thin. In 2019, a small lab in Pennsylvania exploded during a DIY attempt. The blast destroyed three houses. The operator died instantly. The residue in the soil was still detectable six months later.

Medical Use: How the Same Chemical Heals

It sounds contradictory - a powerful explosive used to treat heart disease. But here’s how it works: nitroglycerin releases nitric oxide (NO) in the bloodstream. Nitric oxide relaxes smooth muscle in blood vessels, especially the coronary arteries that feed the heart. This opens up the vessels, lowers blood pressure, and reduces the heart’s workload.

A single sublingual tablet can relieve chest pain in under a minute. That’s why it’s carried by people with known heart conditions. The dosage is tiny - 0.3 to 0.6 milligrams per tablet. The body metabolizes it quickly. Within five minutes, it’s gone.

The same chemical that shatters rock also saves lives. It’s a perfect example of how context, dosage, and delivery determine whether a substance is a weapon or a remedy.

Environmental and Waste Management

Manufacturing nitroglycerin generates hazardous waste: spent acid, wash water, and contaminated filters. These are never dumped. Spent acid is neutralized with lime and then treated in wastewater plants. Wash water is distilled to recover trace nitroglycerin - even a few grams can be reclaimed and reused.

Filters and absorbent materials are incinerated in high-temperature furnaces at 900°C or higher. Any residual nitroglycerin is destroyed before the ash is tested for heavy metals. The final ash is classified as non-hazardous and disposed of in licensed landfills.

Modern plants recycle up to 85% of the acid used. That’s not just good for the environment - it cuts costs. A single plant can save over £200,000 a year on acid purchases alone.

Alternatives and Future Trends

While nitroglycerin is still widely used, especially in medicine, newer compounds are being developed. PETN (pentaerythritol tetranitrate) and RDX are more stable explosives, and they’re replacing nitroglycerin in many military applications. In medicine, long-acting nitrates like isosorbide mononitrate are preferred for daily use because they don’t cause tolerance as quickly.

But nitroglycerin remains irreplaceable for emergency angina relief. No other drug works as fast. And in industrial blasting, its high brisance - or shattering power - makes it ideal for rock fragmentation.

Research is ongoing into encapsulated forms that make it even safer to handle. Scientists at the University of Bristol are testing microcapsules made from biodegradable polymers that release nitroglycerin only when triggered by specific enzymes. This could lead to smarter, targeted heart medications with fewer side effects.